Current Issue

Latest News

Twin Star Home Launches New duraflame®-Branded Electric Fireplaces + A New Acquisition

BOCA RATON, FL - Twin Star Home has expanded its long-standing collaboration with Duraflame with the launch of a new line of duraflame® branded electric fireplaces.

For more than 15 years, Twin Star Home has offered consumers trusted duraflame® stoves, heaters, and compact electric fireplaces, under brand license. This…

Ortal Debuts New Collections

COLUMBUS, OH - With colder weather upon us, Ortal is embracing the season with new collections that blend cozy charm and sculpted design.

For those seeking warmth and realism, Ortal has expanded its Wilderness Collection with a new Birch log option. The addition is powered by Ortal’s first-in-market, patent-pending flame-through-log…

Sunbrella Launches New Signature Throws

BURLINGTON, N.C. - New Sunbrella Signature Throws, an expansion on their indoor/outdoor performance blankets, are now available. The throws offer a soft, sophisticated feel with lasting quality and cleanability—with fade, stain, and mildew resistance—while also being bleachable and machine washable. Available in three patterns: Estate Plaid; Terrace Edge; and Veranda…

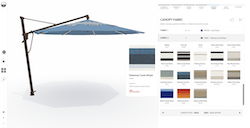

Treasure Garden Unveils New Website and Interactive Design Studio

BALDWIN PARK, CA – Treasure Garden, a manufacturer of outdoor shade products, has unveiled a completely redesigned website and new interactive Design Studio.

These significant updates offer dealers and their customers a more intuitive and engaging experience, simplifying the process of creating the ideal outdoor shade solution.

“We didn’t…

SimpliFire Debuts New Allusion Edge

LAKEVILLE, MN - SimpliFire®, a Hearth and Home Technologies® brand that makes electric fireplaces, recently introduced the Allusion Edge—a linear, electric fireplace that takes style to new lengths. Available in 50-, 60-, 78- and 100-inch widths, the Allusion Edge makes any space feel like home with lifelike digital flames that…